Welding Quality Assurance

Belgrade Welding Institute recently conducted regular supervisory inspection of the compliance of welding operations with the requirements of the EN ISO 3834-2 standard.

The evaluators of the Welding Institute stated that the way of performing welding works at "Naftagas - Technical Services" complies with the requirements of the standard and thus confirmes the validity of the certificate.

The main benefit of applying the ISO 3834 standard is to identify all the factors that can affect the quality of the welded product and that require control at all stages of welding.

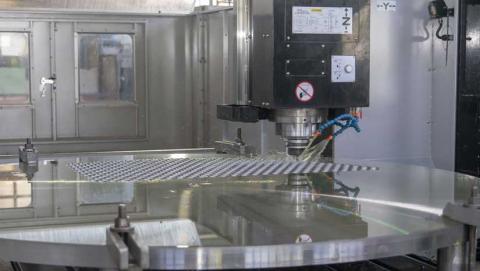

CNC Machine Tool Center

In 2020, Naftagas - Technical Services began the implementation of several projects as part of the equipment modernization program. One of the main investment was CNC portal machining center. In addition to the purchase of the machine and significant sets of cutting and clamping tools, the appropriate software for 3D modeling of work parts (parts that are modeled in software and made on the machine) was procured. Both engineers and operators were trained for successful machine operating.

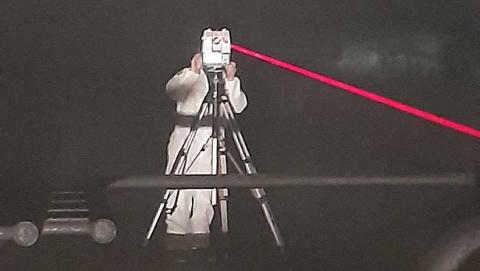

Success of Calibration Laboratory

Calibration Laboratory of NAFTAGAS - Technical Services has successfully calibrated the tank at the OKTA Refinery in Northern Macedonia. Calibration was performed in accordance with all HSE rules, recommendations and protection measures against coronavirus. Cooperation with the OKTA Refinery was established in 2020, after the presentation of laser technology. NAFTAGAS - Technical Services was the first company in the region to start applying electro-optical equipment for calibration and measurement of the geometry of aboveground tanks.